Textile materials are poor conductors of electricity and have high specific resistance. In the process of production, processing and use, fibers and their products are prone to static electricity due to friction, drafting, compression, peeling, electric field induction and hot air drying. Xiaobian will share with you today the case of installing an electrostatic eliminator on a textile setting machine.

Because static electricity will lead to dust collection and contamination during the use of textiles, clothing entangles the human body and produces a sense of adhesion discomfort, and some studies have shown that static electricity stimulation will have an adverse impact on human health. Therefore, it is very important to install an electrostatic eliminator in the textile production process. It can effectively remove the static electricity in the production process, with convenient installation and long service life.

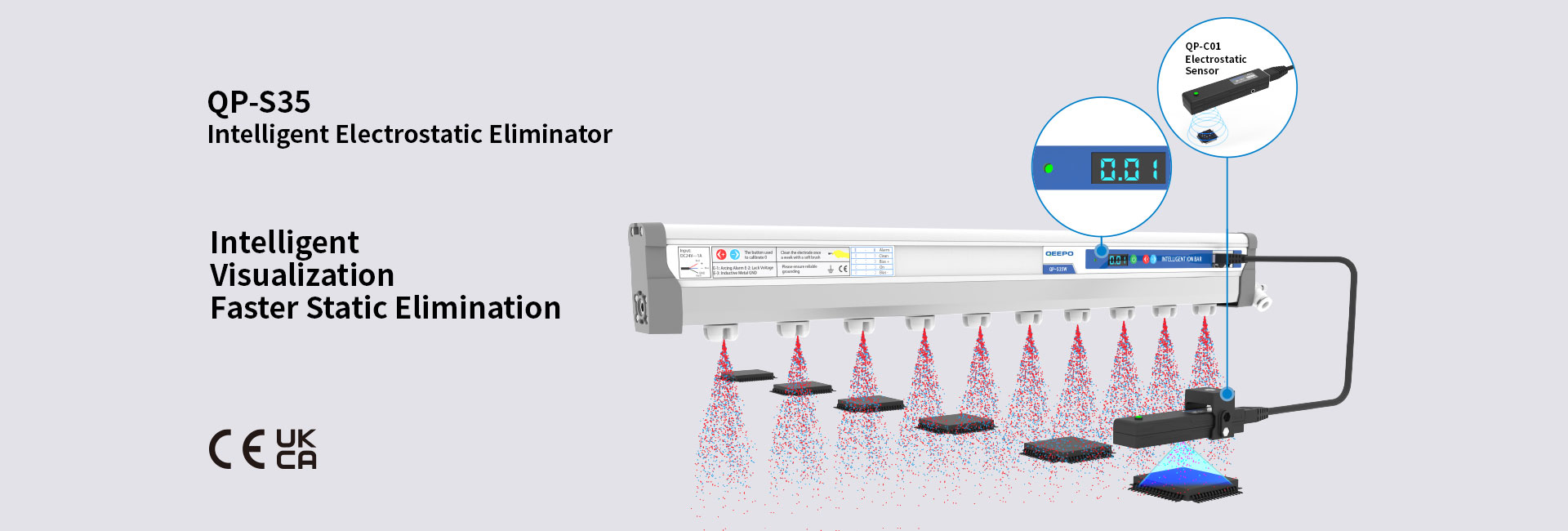

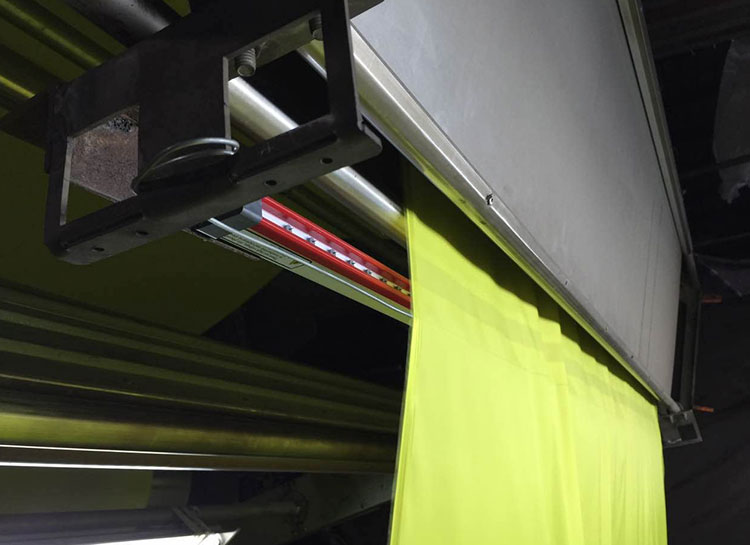

As shown in the figure, Qipu static electricity installs an electrostatic eliminator for the textile setting machine. The installation is simple and the electrostatic removal speed is fast. The size of the electrostatic elimination rod is adapted according to the customer’s machine, and the whole textile can be covered.

In general, we provide stainless steel l bracket fixed on the machine, and the power supply is matched with qp-hd series power supply.

Our technical engineers gave electrostatic solutions on site by checking the parts where static electricity occurs and analyzing the working conditions and environment. The customers are very satisfied with the installation of electrostatic eliminators on the textile setting machine. If you also have electrostatic interference on the textile setting machine, please contact us in time, and we will solve the electrostatic problem for you in time.

Post time: Aug-09-2021