Welcome to our websites!

News

-

Qeepo in productronica China 2023

On April 15, 2023, the 2023 Munich Shanghai Electronic Production Equipment Exhibition came to a successful conclusion! But the excitement continues, and we will remember all the encounters at the exhibition. QEEPO Electrostatics showcases products such as static eliminators, static sensors, sta...Read more -

Six common printing methods to solve static electricity

In order to ensure that the static electricity will not affect the product quality in printing, the production with quality and quantity guaranteed, and at the same time to avoid the occurrence of fire. We must pay strict attention to static electricity and take effective measures and Countermeas...Read more -

What are the consequences of static electricity on printing?

In the actual production process, if printing products are affected by static electricity, there are four common problems: burrs, missing printing, graphic dots, stripes and water drops, which will seriously affect the final quality of printing products. 1、 Burrs caused by static electricity Wh...Read more -

How does an anti static bar work?

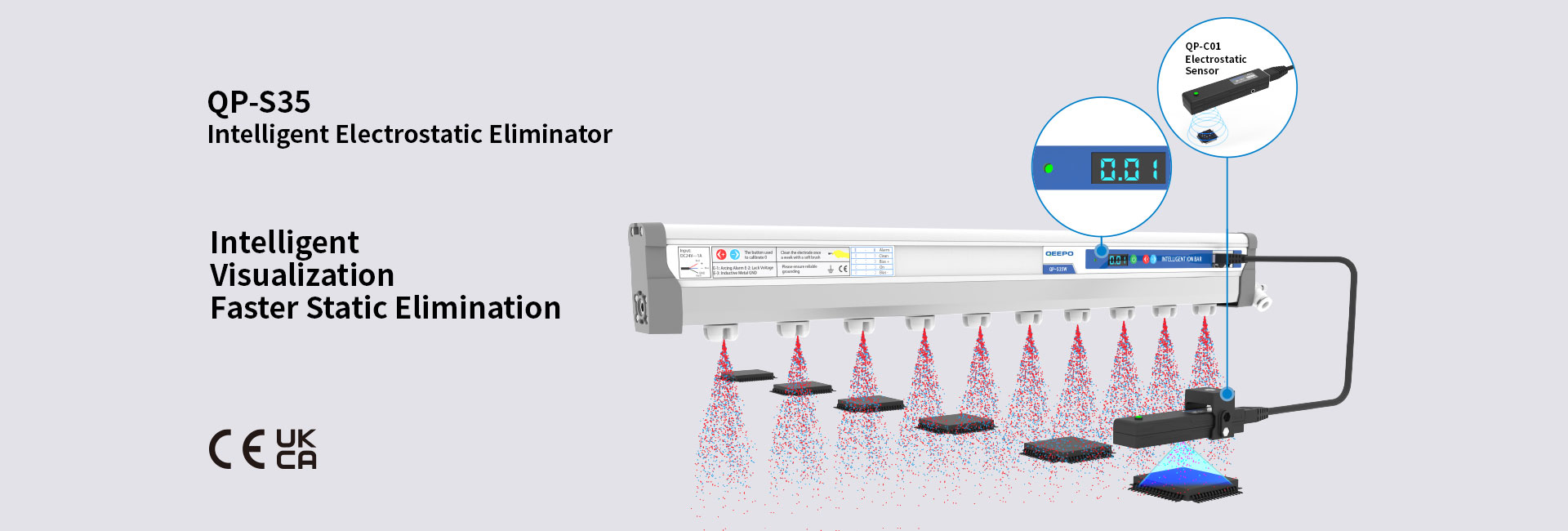

The air contains 78% nitrogen molecules, and most of the rest are oxygen molecules. There is also a small amount of carbon dioxide and water vapor. These molecules in the air have positive or negative ionization due to climatic conditions such as wind, storm, lightning, solar irradiation or radio...Read more -

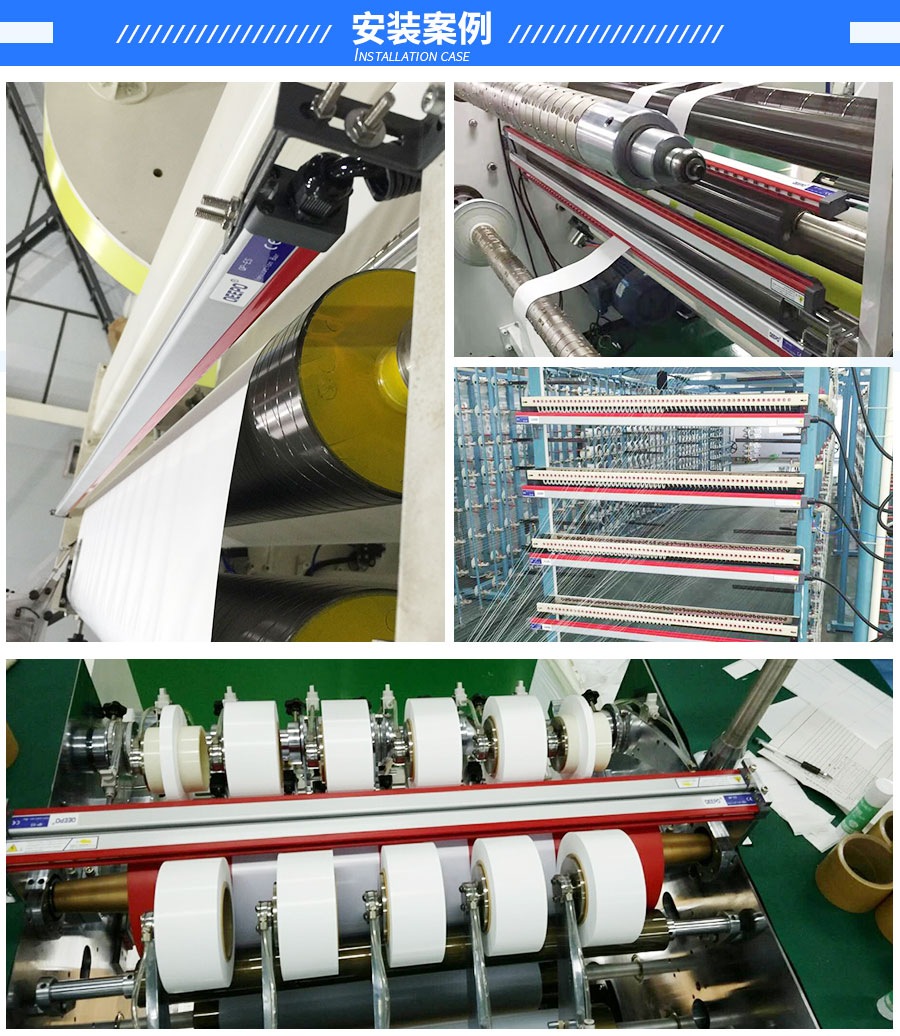

Electrostatic eliminator bar installed in acrylic extruder

The molding process of acrylic is divided into: casting, injection molding, extrusion, thermal molding, etc. Extrusion molding is to extrude the acrylic particles produced by suspension polymerization into acrylic plates, bars, tubes, sheets, etc. This process has high production efficiency and ...Read more -

How to eliminate static electricity on film reels

Common electrostatic hazards in winding and unwinding! The application of rewinding and unwinding runs through all industries, whether it is plastic film, paper, or textiles. In the process of rapid rewinding and unwinding, a lot of friction, peeling and extrusion will be generated between the ma...Read more -

How to solve the electrostatic problem in powder filling

How to solve the electrostatic problem in powder filling The powder will cause electrostatic problems during filling, which will cause serious explosion and production safety problems. Next, qeepo will tell you how to solve the electrostatic problems of powder during filling problem In the proces...Read more -

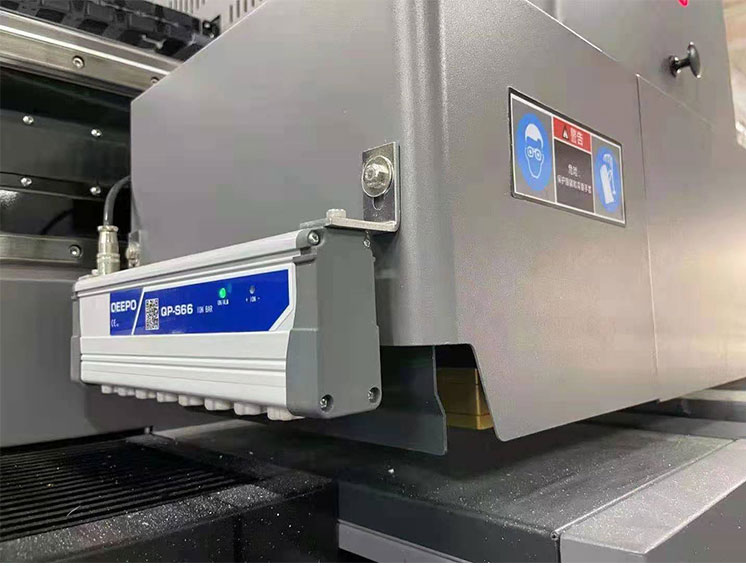

QEEPO QP-S66 anti static ion bar static eliminator for printing machine

The printer is easy to generate static electricity due to material and other reasons, and will cause certain damage to products and equipment. Therefore, installing static eliminator is the correct way to solve the problem of static electricity. How to generate static electricity in the printer:...Read more -

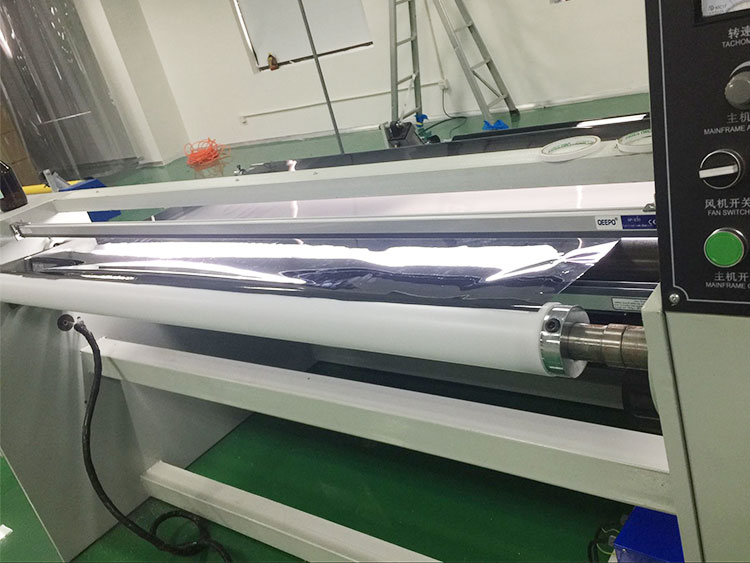

Uses QEEPO static eliminator to solve BOPP film electrostatic problem

Polypropylene is easy to generate static electricity throughout our process-eliminating this static electricity is essential.” “If the static charge is not eliminated, the film roll will be in the post-processing process. May prove to be dangerous. More importantly, the film may not b...Read more -

Aluminum foil thin corona treater treatment machine

Aluminum foil materials have low wettability and are difficult to carry out surface treatment. At this time, we will use corona treatment machine, which can well solve the problem of weak adhesion on the material surface, coarsen the material surface through corona discharge, and prepare ...Read more -

Installation of electrostatic eliminator bar on textile setting machine

Textile materials are poor conductors of electricity and have high specific resistance. In the process of production, processing and use, fibers and their products are prone to static electricity due to friction, drafting, compression, peeling, electric field induction and hot air drying. Xiaobia...Read more -

Installation of electrostatic eliminator for aluminum carbide coating and winding machine

In the printing industry, according to customer requirements, after the product printing production must be bronzing. Hot stamping process needs to use electrochemical aluminum material to achieve. In the process of manufacturing, th...Read more