In modern industrial production, electronic clean rooms play a crucial role, especially in the production process of high-tech products such as semiconductors, precision instruments, and electronic components. However, static electricity has always been a major challenge faced by such workshops. Static electricity may not only cause damage to products, but also affect production efficiency and product quality. Therefore, taking effective measures to eliminate static electricity is crucial for ensuring the normal operation of the dust-free workshop and the stability of product quality. Let’s learn about the electrostatic elimination measures in electronic cleanrooms together with QEEPO!

1、 Application of static elimination equipment

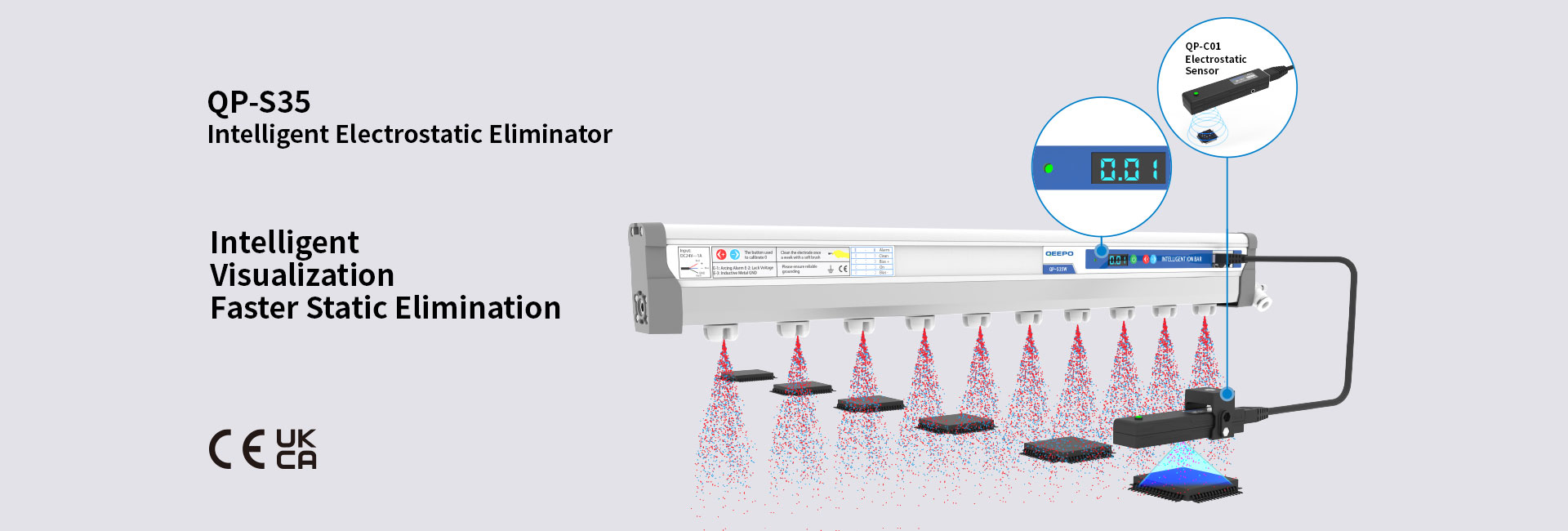

Static elimination equipment is indispensable in electronic cleanrooms. These devices include static eliminators, electrostatic precipitators, etc., which can neutralize or eliminate static electricity in different ways. Firstly, static eliminators can generate charges opposite to the static charges in the workshop, reducing the accumulation of static electricity through neutralization. The electrostatic precipitator utilizes the action of an electric field to adsorb dust particles with static electricity onto the dust collection plate, thereby achieving the purpose of dust removal and eliminating static electricity.

When choosing static elimination equipment, factors such as power, efficiency, and applicability of the equipment need to be considered. Ensure that the selected equipment can meet the actual needs of the workshop and work stably in different environments. In addition, the installation location and layout of the equipment also need to be planned reasonably to ensure that it can cover the entire workshop and effectively eliminate static electricity.

2、 Construction of grounding system

A complete grounding system is an important step in eliminating static electricity. In a dust-free workshop, metal components such as equipment, workbenches, chairs, etc. should be well grounded to dissipate static electricity to the ground. The laying of grounding wires should use materials with good conductivity to reduce grounding resistance and improve grounding efficiency. At the same time, the grounding system should be regularly inspected and maintained to ensure that it is in good condition.

3、 Surface treatment and material selection

The surface treatment of the floor, walls, and other surfaces in the dust-free workshop is also crucial for eliminating static electricity. Materials with good conductivity should be selected for surface treatment, such as anti-static flooring, anti-static coatings, etc. These materials can effectively dissipate static electricity to the ground, reducing the accumulation of static electricity. At the same time, equipment such as workbenches and chairs used in the workshop should also be made of materials with good conductivity to reduce the conduction and accumulation of static electricity.

4、 Humidity control

Humidity is one of the important factors affecting the generation and accumulation of static electricity. In a dust-free workshop, humidity should be controlled within an appropriate range to reduce the risk of static electricity. Usually, it is more appropriate to control the humidity between 40% and 60%. Humidity regulation can be achieved by installing devices such as humidifiers or dehumidifiers.

5、 Personnel anti-static measures

Personnel are also an important source of static electricity in cleanrooms. Therefore, personnel entering the workshop need to take anti-static measures. Firstly, staff should wear clothing that meets anti-static requirements, such as anti-static work clothes, anti-static shoes, etc. These garments can reduce the generation and accumulation of static electricity and prevent damage to products caused by static electricity. Secondly, the staff need to maintain a good grounding state during the operation process, such as using grounding wristbands or gloves. These measures can effectively dissipate the static electricity generated by the human body to the ground, reducing the accumulation and conduction of static electricity.

6、 Electrostatic Monitoring and Control

In order to timely understand the static electricity level in the workshop and take corresponding control measures, it is necessary to install static electricity monitoring equipment. These devices can monitor the static electricity level in the workshop in real time and provide feedback to management personnel. Based on the monitoring results, management personnel can take timely and effective control measures, such as adjusting equipment parameters, changing operating methods, etc., to ensure that the static electricity level is within a controllable range.

In summary, measures to eliminate static electricity in electronic cleanrooms need to be approached from multiple aspects. Through the comprehensive application of static elimination equipment, construction of a complete grounding system, selection of materials with good conductivity for surface treatment, humidity control, personnel anti-static measures, and installation of static monitoring equipment, the impact of static electricity on dust-free workshops and products can be effectively eliminated, ensuring the normal operation of production and the stability of product quality.

Post time: Aug-16-2024