EVA is one of the most critical packaging materials in the production process of solar modules, which seals the upper and lower covers of the battery cells in the middle to protect them; EVA has a high transmittance after melting, which can increase the incidence rate of light and increase the output power of the component; In addition, in the process of component production, lamination is a key link, and the parameter settings of the laminating machine are basically set around the characteristics of EVA, so EVA is crucial for component production.

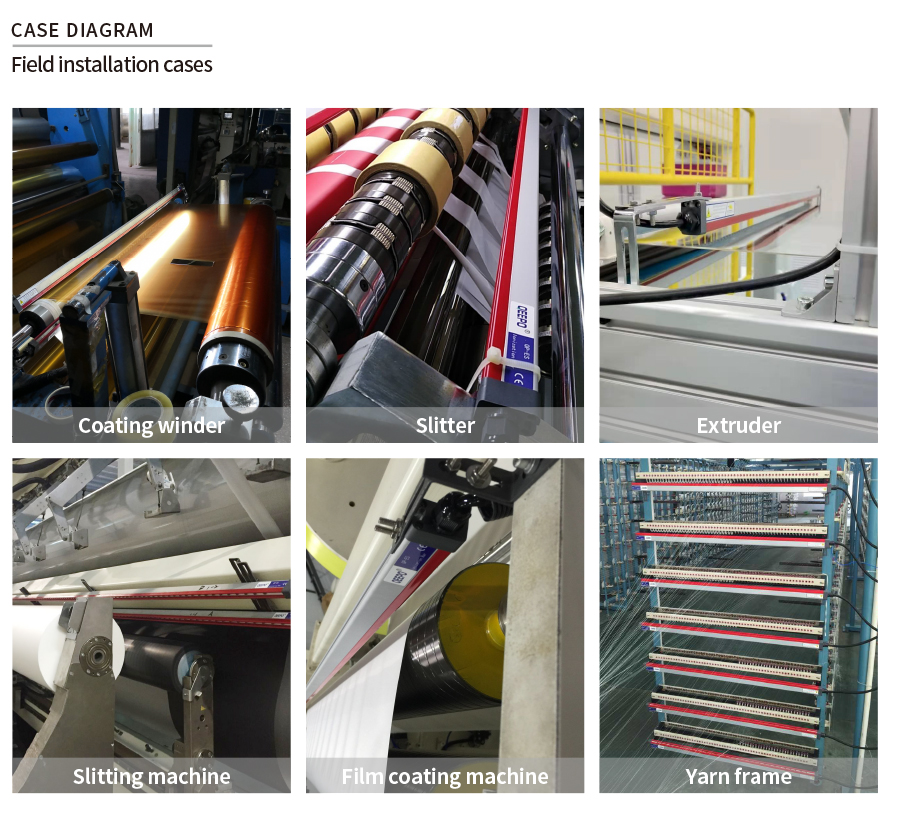

In the production process of EVA film, there are a large number of rolling and rolling processes, which can lead to the generation of high static charges. Among them, the areas with the most severe static electricity are commonly found in the central winding position and automatic cutting process.

Due to the adsorption effect of static electricity, small dust particles with static electricity in the air can adhere to the surface of plastic films and paper prints, producing bright spots, virtual shadows, etc

If the static electricity accumulated in plastic film cannot be released in a timely manner, it may discharge due to the continuous increase of static voltage, forming electric sparks and causing a terrible fire

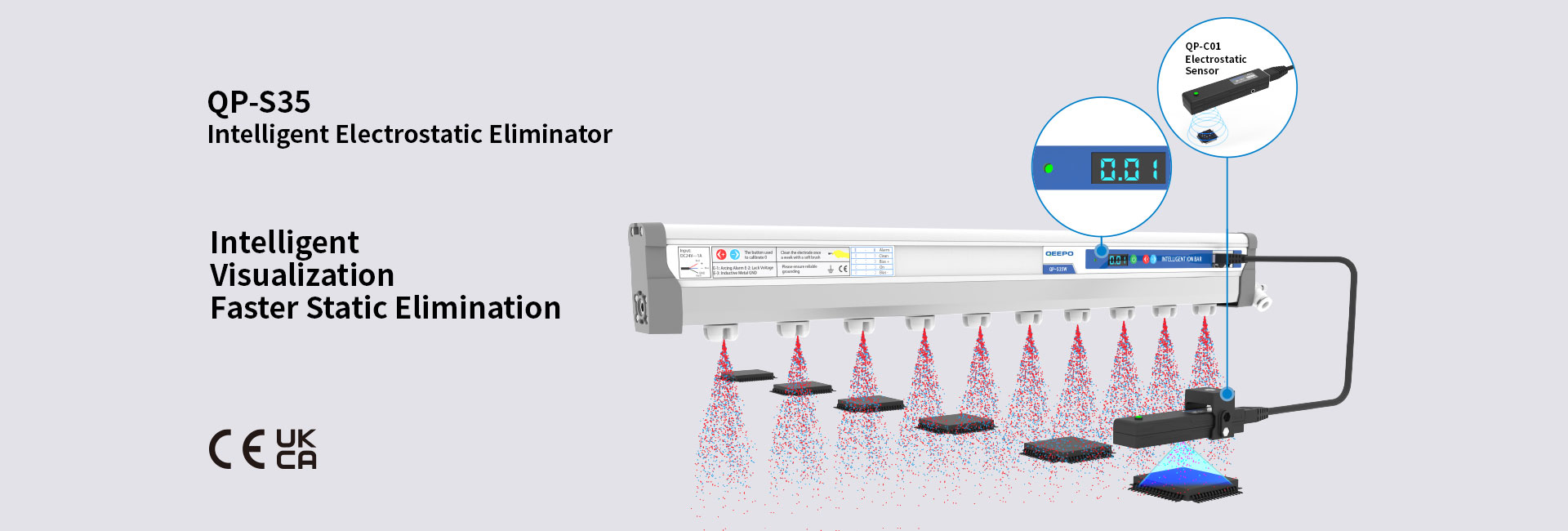

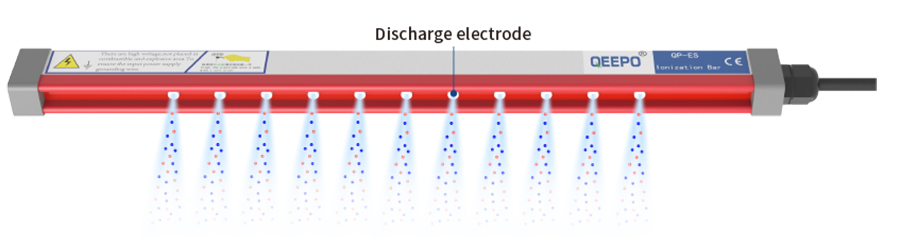

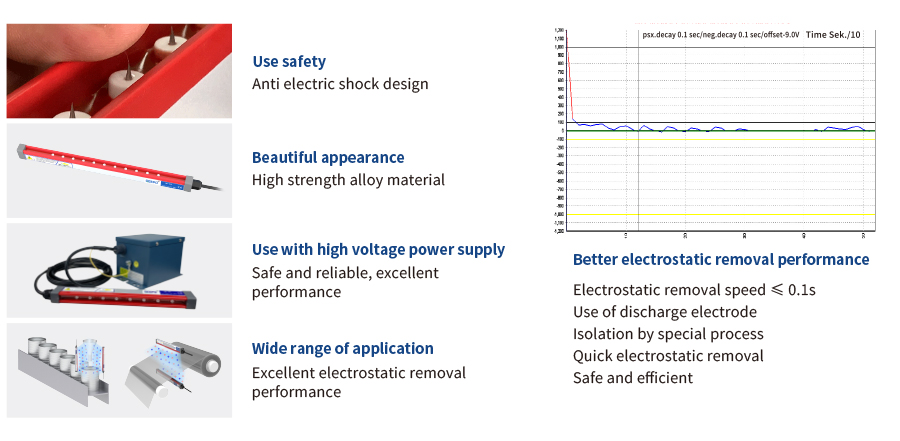

The above electrostatic problems can be solved by installing an electrostatic eliminator, which has a fast electrostatic removal speed and can be customized according to the on-site environment, ensuring safety and efficiency.

Post time: Oct-09-2023