QP-F35A Explosion proof static eliminator bar

QP-F35A Explosion proof static eliminator bar

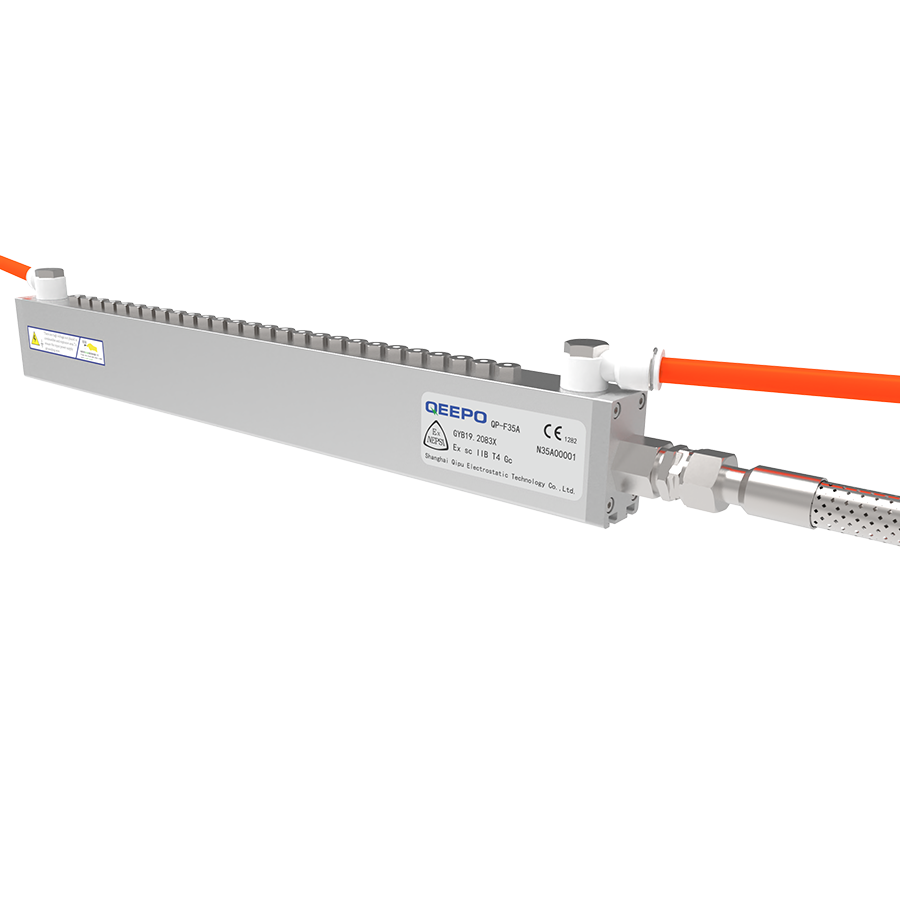

QP-F35A explosion-proof electrostatic eliminator has passed the certification test of national explosion-proof certification authority, and has been tested in ethylene environment. It can be used for electrostatic elimination in class IIB explosive gas environment. The product adopts the built-in structure of the discharge unit. Through the structural design of the compressed air blowing out the ions, the abnormal discharge of the discharge electrode to the external environment is avoided, and the product safety performance is improved; at the same time, the positive and negative ions generated by corona discharge are blown to the material surface by compressed air, which increases the effective working distance of the product; the back T-groove installation structure is convenient and simple.

| TYPE | QP-F35A |

| Working voltage | MAX 7Kv AC |

| Working current | MAX 5mA |

| working frequency | 50/60Hz |

| operation mode | Power frequency AC |

| Working distance | 3~60cm |

| Recommended installation distance | 3~5cm |

| Discharge electrode spacing | 30mm |

| Discharge electrode material | SS. / W / Ti |

| length | 300~2500mm |

| working temperature | 0~50℃ |

| Air pipe size | Φ12 |

| Working air pressure | 0.2~0.5MPa |

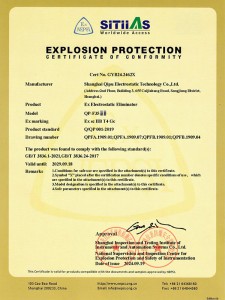

| Explosion proof grade | Ex sc IIB T4 Gc |

| Explosion proof Certificate No | GYB19.0001X |

| Working humidity | 0 ~ 70% RH (no freezing, no condensation) |

| Temperature (23 ± 3) ℃; Humidity (50 ± 5)%; Test voltage ± 1kV ~ ± 100V; | |